METODOLOGY

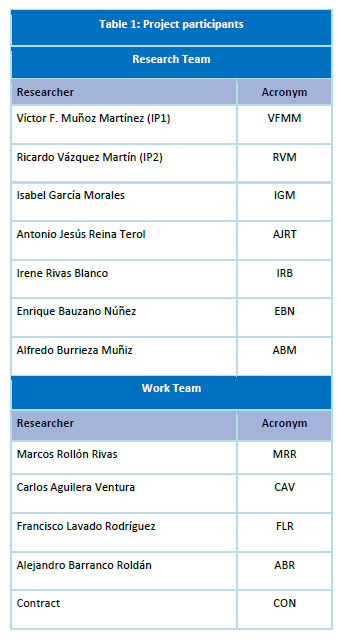

The methodology of this project is based on the establishment of a series of work packages (WP) associated with the objectives of the project. Each WP is divided into a series of tasks whose achievement will result in a deliverable document that reflects the results obtained. The different WP are described below. As additional information, the start and end dates and the acronyms of the participants are specified in each WP. The acronyms of each of the members of the research team are reflected in Table 1.

In order to organise the coordination of the research and work team in the work plan, the working teams A and B described below have been established. The person responsible for each team (IP) has been marked in bold type. On the other hand, a team of experts from an external company has been established (team C).

TEAM A: VFMM, ABM., IGM, IRB, CAV, MRR.

TEAM B: RVM, AJRT, EBN, MCR, CON.

TEAM C: FLR, ABR.

WORKING PLAN

| Working package 1 - Identification of the collaborative industrial environments | |

|---|---|

| Start and end date: M1 – M6 | Participants: TEAM A, TEAM B, TEAM C. |

| Definition of a robotic cell, in cyber-physical system configuration, capable of performing human-robot collaborative tasks in the field of inspection, assembly and loading/unloading. Prerequisites: None |

|

| Tasks: | |

| T1.1. Identification of tasks that can be performed collaboratively. The basic actions, the conditions for executing them and the results they produce will be identified. Classification of tasks and the different levels of interaction and sequences of operation during human-robot collaboration. T1.2. Catalogue of basic actions for the human and the robot with their characteristics (level of robot autonomy, precision degree and execution times) and metrics that guarantee the execution of the identified tasks. T1.3. Failure mode analysis of the selected tasks and elaboration of failure catalogues with their characteristics. Faults are considered to be poor execution or poor sequencing. T1.4. Detailed definition of the cyber-physical system and its functionalities (see figure 1), including the design of the physical scenario (inputs and outputs of the work cell, electrical schematics, collaborative robot sensors and sensors from the Virtual Reality equipment), the design of the Digital Twin and the planning and diagnostic modules. This definition will take into account the scalability and configuration of the system according to the tasks identified in task 1.1, to incorporate different types of sensors, number of robots, etc. T1.5. Definition of two experiments and the validation method. This task also includes the definition of the metrics that will be used to validate the system and the quality of the task. |

|

| Deliverables: | |

| D1.1. Catalogue of basic actions and failures modes. D1.2. Definition of the overall system and design of experimental testing.. |

|